1. Chinangwa chekuedza kwe mold?

Zvizhinji zvekuremara kwakaumbwa kunoitika panguva yechigadzirwa plasticizing uye molding process, asi dzimwe nguva zvine chekuita neasinganzwisisike mold dhizaini, kusanganisira kuwanda kwe cavities; dhizaini yeinotonhora / inopisa mumhanyi system; rudzi, chinzvimbo uye saizi yegedhi jekiseni, pamwe nechimiro chechigadzirwa geometry pachayo.

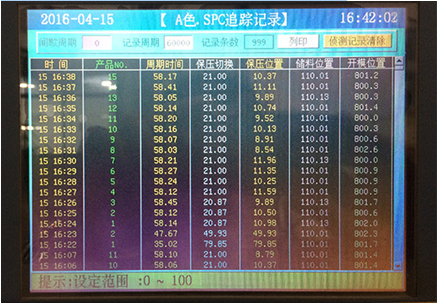

Uye zvakare, panguva chaiyo yekuyedza maitiro, kuitira kuti iite kushaikwa kwekugadzira mold, vashandi vekuyedza vanogona kuseta isina kururama parameter, asi iyo chaiyo data renji yehuwandu hwekugadzira inodiwa nemutengi yakanyanya kushomeka, kana iyo parameter marongero ne. chero kutsauka kudiki, mhando yekugadzirwa kwehuwandu inogona kutungamira kune kure kupfuura iyo inobvumirwa shiviriro renji, zvinozoita kuti goho rekugadzira rive richidzikira, mutengo uchikwira.

Chinangwa chekuyedzwa kwe mold ndechekutsvaga iyo yakakwana maitiro paramita uye mold dhizaini. Nenzira iyi, kunyange zvinhu, muchina parameter kana zvakatipoteredza zvinhu zvine chimwe chinhu chinoshanduka, mold ichiri kukwanisa kuchengetedza yakagadzikana uye kugadzirwa kwemazhinji pasina kukanganisa.

2. Mold kuedza Matanho atiri kutevera.

Kuti tive nechokwadi chekuti muyedzo we mold ndeyechokwadi, timu yedu inoteerera pazasi matanho.

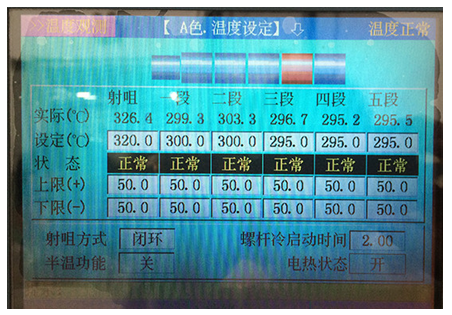

Danho 1. Kuseta muchina wejekiseni "nozzle barrel" tembiricha.

Izvo zvinofanirwa kucherechedzwa kuti yekutanga tembiricha yekumisikidza yebhari inofanira kunge yakavakirwa pane zvekushandisa kurudziro. Uye zvino zvichienderana neyakagadzirirwa mamiriro ekugadzira yakakodzera-tuning.

Pamusoro pezvo, tembiricha chaiyo yechinhu chakanyunguduka mudhiramu inofanira kuyerwa ne detector kuti ive nechokwadi chekutevedzera skrini inoratidzwa. (Tave nemakesi maviri ayo maviri akasiyana tembiricha anosvika makumi matatu ℃).

Danho 2. Kuisa tembiricha mold.

Saizvozvo, yekutanga tembiricha yekumisikidza ye mold inofanirwawo kuve yakavakirwa pane yakakurudzirwa kukosha inopihwa nemupi wezvinhu. Naizvozvo, pamberi pekuyedzwa kwepamutemo, tembiricha yenzvimbo ye cavities inofanira kuyerwa nekurekodhwa. Kuyera kunofanirwa kuitwa munzvimbo dzakasiyana kuti uone kana tembiricha iri pakati nepakati, uye kurekodha mhedzisiro inoenderana yekutevera-up mold optimization reference.

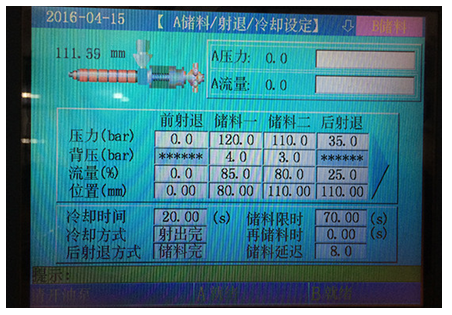

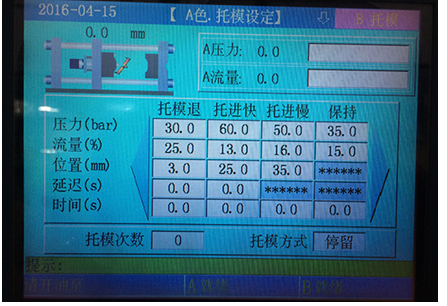

Danho 3. Kuisa parameters.

Zvakadai sepurasitiki, kudzvanywa kwejekiseni, kumhanya kwejekiseni, nguva yekutonhodza, uye screw speed zvinoenderana neruzivo, wobva waigonesa nemazvo.

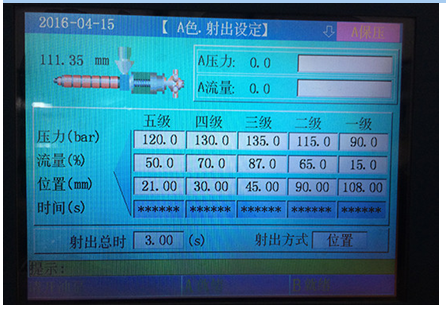

Nhanho 4. Kutsvaga "injection-holding" shanduko yekuchinja panguva yekuzadza bvunzo.

Iyo yekushandura nzvimbo ndiyo yekuchinja kubva pajekiseni nhanho kuenda kune yekumanikidza inobata chikamu, inogona kuve iyo jekiseni screw chinzvimbo, nguva yekuzadza uye kumanikidza kwekuzadza. Ichi ndicho chimwe cheakanyanya kukosha uye akakosha ma paramita mune jekiseni molding process. Muyedzo chaiyo yekuzadza, mapoinzi anotevera anofanirwa kuteverwa:

- Kumanikidzwa kwekubata uye kubata nguva panguva yekuedzwa kunowanzoiswa kune zero;

- Kazhinji, chigadzirwa chinozadzwa kusvika 90% kusvika 98%, zvichienderana nemamiriro chaiwo emadziro emadziro uye mold structure design;

- Sezvo kumhanya kwejekiseni kuchikanganisa chinzvimbo chenzvimbo yekutsikirira, zvinodikanwa kusimbisazve nzvimbo yekutsikirira nguva yega yega kana jekiseni rinomhanya richichinjwa.

Munguva yekuzadza nhanho, isu tinogona kuona kuti zvinhu zvinozadza sei muforoma, tichitonga kuti ndezvipi zvinzvimbo zviri nyore kuve nemhepo musungo.

Nhanho 5. Tsvaga muganho weiyo chaiyo jekiseni pressure.

Iyo jekiseni yekumanikidza kumisikidzwa pachiratidziri ndiyo muganho weiyo chaiyo jekiseni kudzvanywa, saka inofanirwa kugadzikwa yakakura kupfuura kudzvanywa chaiko. Kana yakadzikira uye yobva yaswededzwa kana kupfuurwa neiyo chaiyo jekiseni kumanikidza, iyo chaiyo jekiseni kumhanya inozodzikira otomatiki nekuda kwekudzikira kwemagetsi, izvo zvinozokanganisa nguva yejekiseni uye kutenderera kwekuumbwa.

Nhanho 6. Tsvaga yakanakisa jekiseni kumhanya.

Kumhanya kwejekiseni kunotaurwa pano ndiko kumhanya uko nguva yekuzadza ipfupi sezvinobvira uye kudzvanywa kwekuzadza idiki sezvinobvira. Muchiitiko ichi, zvinotevera zvinofanirwa kucherechedzwa:

- Zvizhinji zvinogadzirwa pamusoro pehurema, kunyanya padyo negedhi, zvinokonzerwa nekumhanya kwejekiseni.

- Multi-stage jekiseni rinongoshandiswa chete kana jekiseni rimwechete risingakwanise kuzadzisa zvinodiwa, kunyanya muyedzo yekuumbwa.;

- Kana iyo mold chimiro chakanaka, kukosha kwekumisikidza kwakaringana, uye kumhanya kwejekiseni kwakaringana, ipapo chigadzirwa chemwenje chikanganiso hachina hukama hwakananga nekumhanya kwejekiseni.

Nhanho 7. Gadzirisa nguva yekubata.

Nguva yekubata inodaidzwawo senge jekiseni gedhi yakasimba nguva. Kazhinji, nguva inogona kugadziriswa nekuyera. zvichiita kuti pave nenguva yakasiyana yekubata, uye iyo yakakwana yekubata nguva ndiyo nguva iyo uremu hweforoma hunowedzerwa.

Danho 8. Optimizing mamwe parameters.

Zvakadai sekubata pressure uye clamping force.

Ndatenda zvikuru nenguva yenyu yekuverenga pano.ziva zvakawanda nezve mold test

Nguva yekutumira: Jul-25-2020