Plastic mold chishandiso chinofananidzwa nemichina yekuumba epurasitiki muindasitiri yekugadzira mapurasitiki kuti ipe zvigadzirwa zvepurasitiki kurongeka kwakazara uye saizi chaiyo. Zvinoenderana nemhando dzakasiyana dzekuumba nzira, inogona kukamurwa mumhando dzakasiyana dze mold.

1. Yakakwirira-yakawedzerwa polystyrene molding inofa

Imhando ye mold inoshandisa inowedzera polystyrene (bead material inoumbwa ne polystyrene uye foaming agent) mbishi kugadzira furo kurongedza zvinhu zvemhando dzakasiyana dzinodiwa.

Nheyo yacho ndeyekuti polystyrene inowedzeredzwa inogona kuputirwa muforoma, kusanganisira maviri marudzi eakapusa ekushandisa manyorero uye hydraulic yakatwasuka-kuburikidza nefuro mapurasitiki mold, ayo anonyanya kushandiswa kugadzira zvigadzirwa zvekurongedza zvezvigadzirwa zvemaindasitiri. Zvinhu zvekugadzira molds dzakakandwa aluminium, simbi isina tsvina, bhuronzi, nezvimwe.

2. Compression mold

Kusanganisira compression molding uye jekiseni kuumba maviri akaumbwa mold mhando. Iwo imhando ye mold inonyanya kushandiswa kuumba thermosetting mapurasitiki, uye yavo inoenderana midziyo yemuchina wekudhinda.

Compression molding nzira Zvinoenderana nehunhu hwepurasitiki, mold inodziya kune tembiricha yekuumbwa (kazhinji 103 ° 108 °), ipapo iyo yakayerwa yekuumbwa yehupfu inoiswa mugomba rekuumbwa uye mukamuri yekudyisa, mold yakavharwa, uye iyo plastiki inopisa pasi pekupisa kukuru uye kudzvinyirira kukuru. Nyoresa kuyerera kwe viscous, simbisa uye gadzira mushure meimwe nguva yenguva, uye uve iyo inodiwa chigadzirwa chimiro.

Musiyano uripo pakati pejekiseni molding uye compression molding ndeyekuti hapana yakaparadzana yekudyira imba. Iyo mold yakavharwa isati yaumbwa, uye ipurasitiki inopisa mukamuri yekudyisa uye inova viscous flow state. Pasi pechiito chekumanikidza, inogadziriswa uye inosvinwa mumhango ye mold kuti iome uye iite.

Iyo compression mold inonyanya kuumbwa nemhango, mhango yekudyisa, giding mechanism, ejecting parts, heat system, etc. Majekiseni molds anoshandiswa zvakanyanya mukurongedza zvinhu zvemagetsi. Zvishandiso zvinoshandiswa mukugadzira compression molds zvakangofanana nemajekiseni mold.

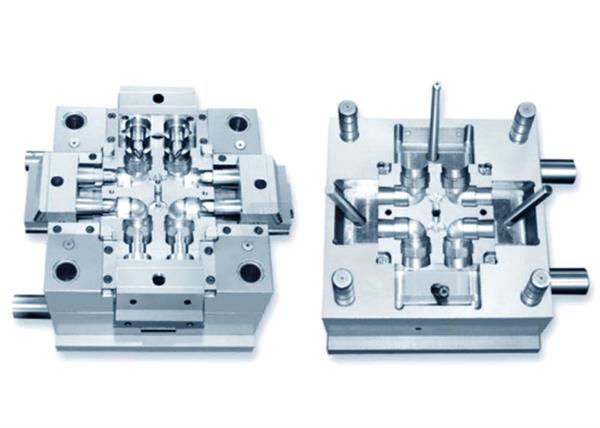

3. Jekiseni mold

Iyo inonyanya kuumba mold iyo inonyanya kushandiswa mukugadzirwa kwe thermoplastic parts. Midziyo yekugadzira inoenderana nejekiseni mold ijekiseni rekuumba muchina. Plastiki inotanga kupisa uye kunyungudutswa mumudziyo wekupisa pazasi pemuchina wekuumba jekiseni. Pasi pekusundirwa kweplug, inopinda mugomba remugodhi kuburikidza nejekiseni rekugadzira muchina muromo uye yekudurura sisitimu ye mold, uye purasitiki inotonhodzwa uye kuomeswa kuti iite, uye chigadzirwa chinowanikwa nekudhirowa.

Chimiro chayo chinowanzo umbwa nekugadzira zvikamu, kudira sisitimu, kutungamira zvikamu, kusunda-kunze meshini, tembiricha yekudzora system, exhaust system, zvikamu zvinotsigira uye zvimwe zvikamu, uye inogadzirwa nesimbi yepurasitiki mold. Iyo jekiseni yekuumba maitiro inowanzo fanirwa chete kugadzirwa kwe thermoplastic zvigadzirwa. Zvigadzirwa zvepurasitiki zvinogadzirwa nejekiseni molding process zvakapamhama. Kubva pane zvinodikanwa zvezuva nezuva kusvika kune dzakasiyana siyana dzakaomarara midziyo yemagetsi uye zvikamu zvemotokari, zvese zvinoumbwa nemajekiseni mold. Imwe yedzakanyanya kushandiswa nzira dzekugadzirisa mukugadzira zvigadzirwa zvepurasitiki.

4. Vhura mold

Mold inoshandiswa kugadzira zvigadzirwa zvepurasitiki zvisina hollow (senge mabhodhoro ezvinwiwa, zvigadzirwa zvemakemikari zvemazuva ese uye zvimwe midziyo yekurongedza). Iyo fomu yekuvhuvhuta kuumba inonyanya kusanganisira extrusion blow molding uye jekiseni molding zvinoenderana neiyo process musimboti. Nheyo yacho inonyanya kusanganisira extrusion blow molding, jekiseni kuvhuvhuta, jekiseni rekuwedzera kuvhuvhuta (inowanzozivikanwa sejekiseni kutambanudza kuvhuvhuta), multi-layer blowing molding, sheet blow molding, etc. Midziyo inoenderana nekuvhuvhuta kwezvigadzirwa zvisina mhango inowanzonzi plastiki. blow molding muchina, uye blow molding inokodzera chete kugadzirwa kwe thermoplastic zvigadzirwa. Mamiriro ekuputira mold ari nyore, uye zvinhu zvinoshandiswa zvinonyanya kugadzirwa nekabhoni.

5. Extrusion kufa

Mhando ye mold inoshandiswa kugadzira inoenderera-yakaumbwa zvigadzirwa zvepurasitiki, inozivikanwawo se extrusion molding head, inoshandiswa zvakanyanya mukugadzirisa mapaipi, mabara, monofilaments, mahwendefa, mafirimu, waya uye tambo yekuvharisa, profiled zvinhu, nezvimwe.

Iyo inoenderana nekugadzira michina ipurasitiki extruder. Nheyo yacho ndeyokuti plastiki yakasimba yakanyungudutswa uye yakagadziriswa pasi pemamiriro ekupisa uye screw rotation ye extruder, uye inogadzirwa muchikamu chimwe chete chemuchinjikwa sechimiro chefa kuburikidza nekufa kwechimwe chimiro. Zvigadzirwa zvepurasitiki zvinoenderera. Zvigadzirwa zvayo zvekugadzira zvinonyanya kabhoni simbi yekugadzira, alloy maturusi, nezvimwewo, uye mamwe maextrusion anofa akaiswawo nezvinhu zvinopfekwa senge diamond pazvikamu zvinoda kusapfeka.

Iyo extrusion maitiro anowanzo akakodzera chete kugadzirwa kwe thermoplastic zvigadzirwa, izvo zvakasiyana zvakanyanya nejekiseni molds uye compression mold muchimiro.

6. Blister mold

Mold inoshandisa maplate epurasitiki nemasheets sezvishandiso kugadzira zvimwe zvigadzirwa zvepurasitiki zviri nyore. Panyaya yekupfava, inoremara uye inonamirwa kugomba refodya kuti iwane chinodiwa chakaumbwa chigadzirwa, icho chinonyanya kushandiswa mukugadzira zvimwe zvinodiwa zvezuva nezuva, chikafu uye matoyi ekurongedza zvigadzirwa.

Nguva yekutumira: Feb-12-2022